Tile Gasket™

Tile Gasket™

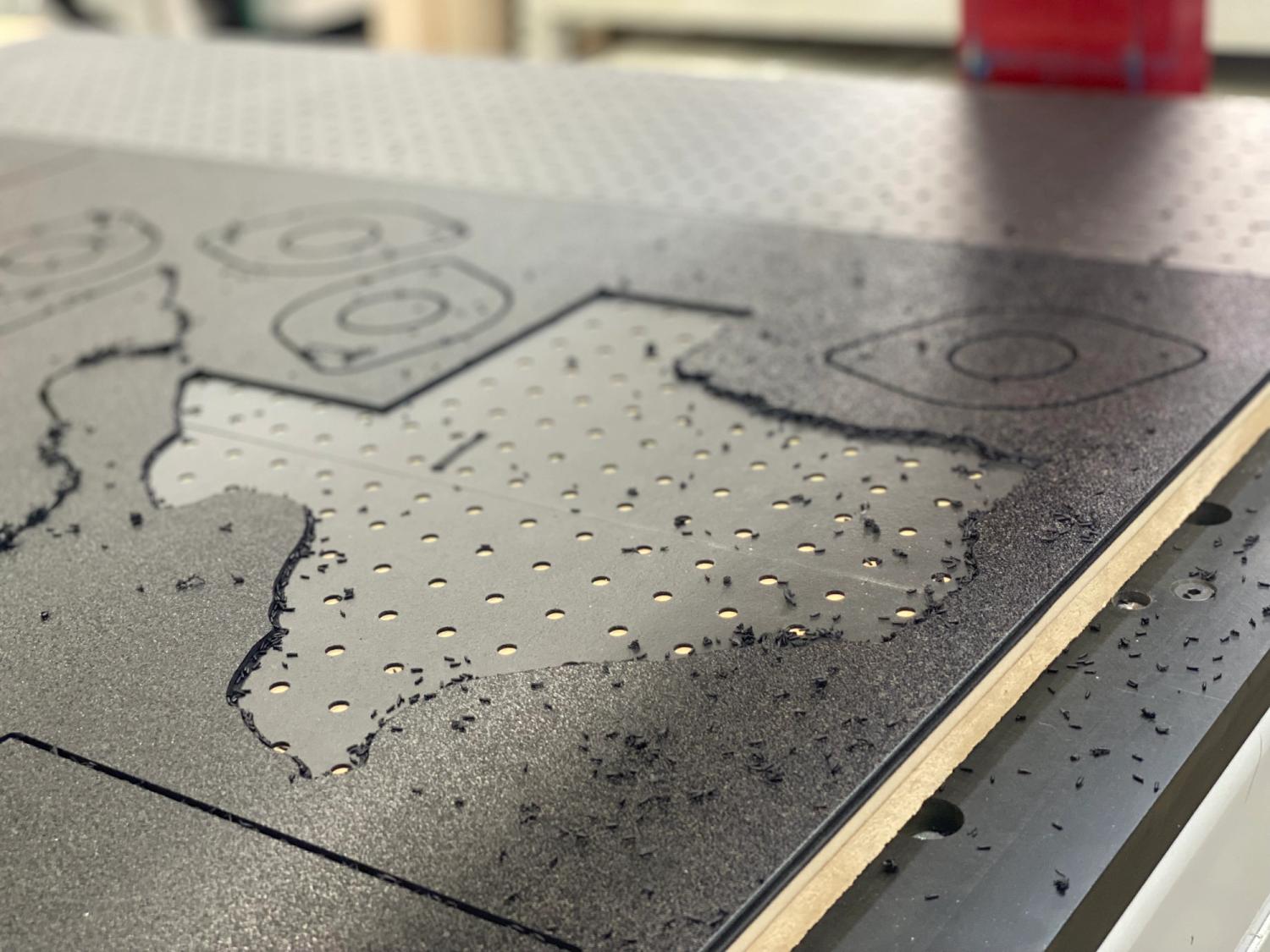

Our Patent pending Tile Gasket™ products were created for our Nested Base Manufacturing customers. For those looking for the benefits of a proper gasketing solution, but jobs that are constantly changing, these tiles offer the best solution. By covering an entire MDF porous spoil board with these non-porous tiles, not only is the vacuum less likely to leak from tool paths that are being cut, but the sum of 1/4″ holes creates a universal clamping system that holds entire sheets more effectively.

This represents the most recent addition to the All Star CNC Products Gasketing Line. Utilizing our Cover Gasketing material, the Tile Gasket™ products are pre-perforated with 1/4″ holes, every 1″ spaced apart. It has a similar pattern to a peg board you would find on a work bench. But each of these 1/4″ holes creates a vacuum clamp, something that does not happen with gasketing material. It is a fantastic option for our customers who run spoilboards and constantly changing parts.

There are two advantages to utilizing the Tile Gasketing concept:

1) Improved vacuum efficiency by creating a gasketed vacuum clamp chamber area under any part, and

2) The tiles seal the surface on a porous spoilboard, such as MDF. A sealed-surface spoilboard to prevent vacuum pressure loss through the surface of the spoilboard as parts are being routed. This leak is the reason the end of a nest does not cut with the same quality as the start of a program: continued vacuum loss through the surface of the spoilboard as tool paths are exposed.

These tiles will cover an entire porous MDF surface, creating thousands of mini suction cups to hold parts. When customers are doing Nested Base Manufacturing, but want to the benefit of vacuum clamping, these tiles are the solution. Not only will they create vacuum clamps to hold the sheets, but it prevents vacuum leak from occurring through the channels of an exposed spoilboard. An improved vacuum hold-down system in an ever-changing job environment is why the users of this item make it a part of their Nested Base Manufacturing process. The product, just like all of the gasketing products, can vary in both thickness and density, to fit each customer’s unique set of variables. Not all users are attempting to hold the same substrates.

Gallery

Who is Tile Gasket™ intended for?

Those wanting better vacuum efficiency out of the MDF spoilboards for holding parts. All Star CNC pioneered "Vacuum Clamping", a much more effective and powerful way to hold parts in comparison to "Down-Drafting" through an open MDF spoilboard. Tile Gasket™ is a game-changer in production work by sealing the majority of a porous, drafty spoilboard, and creating small vacuum chambers within its small perforation holes. This develops a negative air pressure differential under the parts, positive atmosphere pressure on top, developing orders of magnitude greater parts holding by comparison.

How to utilize Tile Gasket™

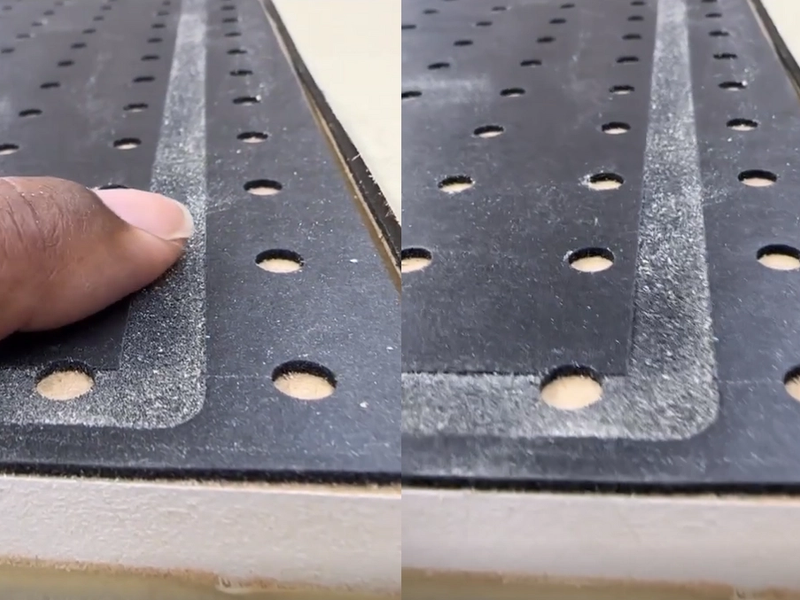

The Tile Gasket™ is applied to a clean spoilboard, and the gasket becomes the spoiled surface, not the board. Readjust the Z-Depth of the cutting for the new surface dimensions. As the Tile Gasket™ inevitably will wear, simply fly-cut the remaining gasket away and re-apply it to a fresh surface. The typical lifespan, when used correctly is 400 working hours or greater.

What Tile Gasket™ solution is best for me?

Covering an entire spoilboard with Tile Gasket™ is a great option for those customers who are looking to get finished parts in a single pass, no tabs or onion skins. The same can be done in a smaller zoned area. Or even a “secondary spoilboard” that comes on and off your work area as needed. Our clients have excellent success cutting even the smallest parts in a single pass.

Tile Gasket “rules of thumb”

- Should be applied to a freshly cut spoilboard and wiped clean.

- 95% of the surface area of a drafty MDF spoliboard is covered, so 95% of the vacuum pull is concentrated to only 5% of the surface area of the vacuum ports.

- Using Tile Gasket™ and Vacuum Clamping methodology has little to do with CFM or the volume of air that you can pull, but more focusing on the strength of the vacuum pull. We've saved coutless custoemrs the need to buy larger or more vacuum pumps.

- Set tooling to cut barely cut into gasketing material for repeat use

- Cutting through gasketing material is not the end of its usefulness

- Ensure that your Grid Gasket is fresh or replaced as regular maintenance is crucial for proper Tile Gasket™ performance.

Customer feedback on the importance of Z-depth and cutting material on Tile Gasket™ for long life:

“Having a machine that holds zero perfectly over the entire table is important to get the most useful life out of the tiles. I used mine for around 6-7 months, 95% of my cuts were profile (through) cuts. I had a job that required a 100% flat level spoilboard and had eaten away one particular area enough that I had to remove the tiles. The trick I use is to zero the bit to the tile surface and then in my design program I add .003” to my cut depth. Ex: .500” thick material setting, .503” depth of cut. This means I am only skimming the tile surface by .003”, the thickness I purchased was 1/16” thick .0625”

Tile Gasket in production environments using Off-Loaders