On Board Gasketing

On Board Gasketing

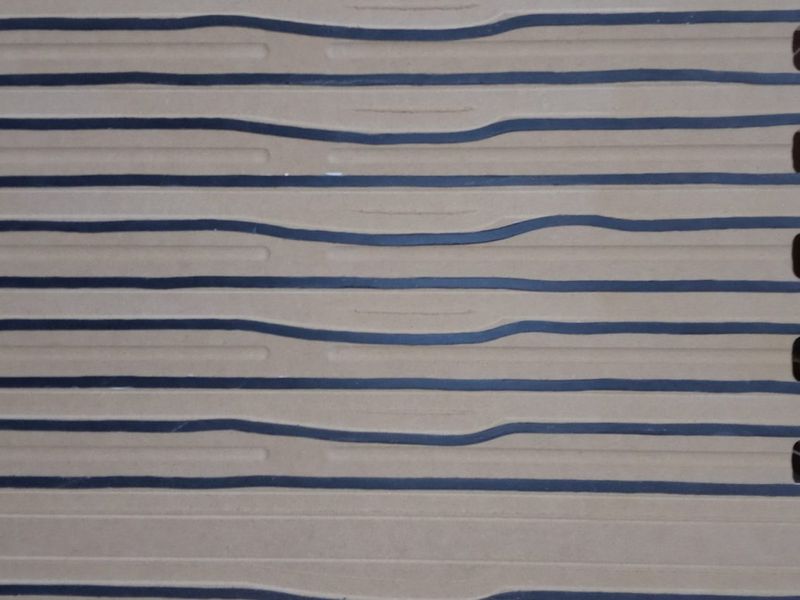

On Board Gasketing is an adhesive-backed material that is placed directly on the surface of a fixture or spoil board. It creates excellent holding power when doing short-run jobs and a dedicated fixture is not desired. The vacuum that is centralized and concentrated to a part like this is not possible without a gasket solution.

The quickest and easiest way to create a vacuum clamp is with On-Board Gasketing. It is an extremely quick and cost effective way to improve vacuum hold performance without having the spend the time or materials on making dedicated fixtures. create a vacuum clamp, the ideal solution is On-Board Gasketing. It is the easiest way to improve a vacuum hold down application on an MDF spoilboard vs downdraft hold only, and frankly it is not even a fair fight. When introducing gasketing, it changes the hold down environment from a simple downdraft system to a vacuum clamping, suction-cup style system. It is a different science. The vacuum clamp hold that is achieved with gasketing is 20X the vacuum pressure of a simple down-draft system. A simple flick of a finger can move a part on a MDF spoilboard, while a rubber mallet may not move a part out of place that is properly gasketed.

A few things to consider when evaluating On-Board Gasketing Products:

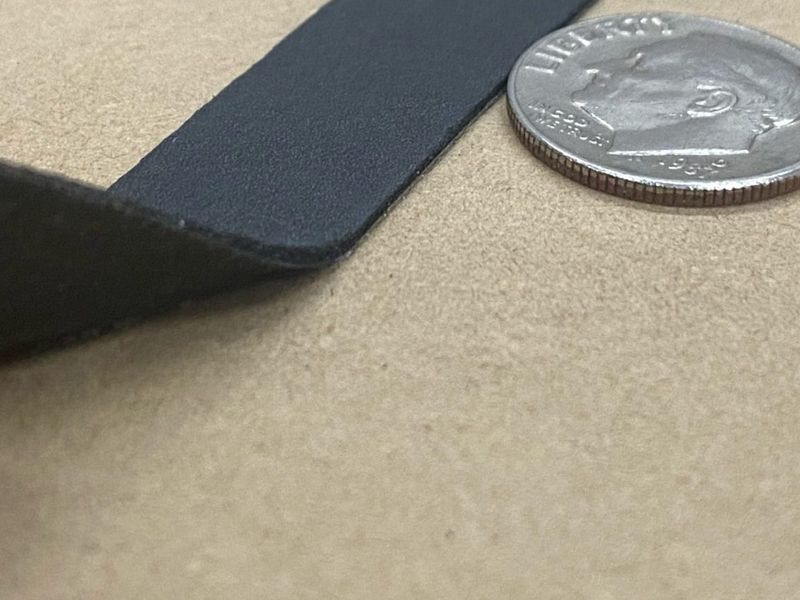

- The thinner the better. Thinner surface mounted gasket creates less part vibration. But enough thickness is needed to counter-act the variances of the material looking to be held.

- It is why the 1/32″ thick CR 03 material is the most common for plastics applications

- The CR 06 material most common among woodworkers

- The CR 12 material when working with materials that have a lot of variances.

- The CR 06 38 3/8″ width is the most commonly ordered. Narrow widths (1/4″and 1/8″) can help with tighter areas. Wider size like 1/2″ and more are also available.

- Lower Density products (CE series) are typically ordered by customers with low-powered vacuum systems, such as home built machines and hobbyists.

- Firm Density Products (IR series) are for very heavy weight products that need a strong gasket to hold up under the weight of the material, not just vacuum pull.

Gallery

Who is On Board intended for?

Intended for those shops that are looking to vacuum clamp parts, but cannot justify the volume, time, or material of making a Dedicated Fixture. Those customers who run prototypes, improve the clamp on small parts, or avoid bracket clamping, adhesives, or screwing parts in place.

How to utilize On Board Gasket:

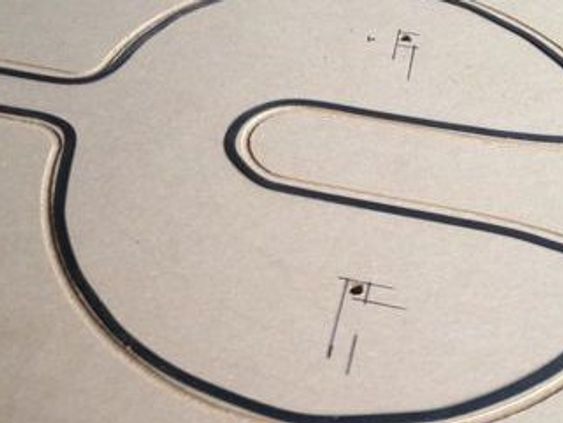

Easily take advantage of an On-Board Gasket by running a ghost pattern of a part’s CAD design. This provides a visual tool path pattern into the spoilboard as a guide, and simply use the peel-and-stick gasket to the interior of the tool path, making a vacuum chamber area beneath each part.

What On-Board Gasket is best for me?

All Star On Board gasket can vary in thickness, width, and density for the greatest flexibility for optimal vacuum clamping force depending on your part or project. Our experts can help you select the exact product, specific to your project, and guide you to a perfect seal.

On-board gasketing “rules of thumb”

- The thinner the better

- The firmer the better

- Gasketing never zeros-out, affecting Z-Depth

Our Pen Holding Tool is the perfect compliment to our On Board Gasketing. Simply trace your part on a spoilboard and apply the On Board Gasket directly to the traced outline or inside of the tool path. No more guessing, just trace and apply for the perfect seal for vacuum clamping your parts. More info and purchase here.