In Board Gasket Pictures

A customer utilizing a Komo Machine CNC router to make high-end, custom home furnishings and games. They created a dedicated fixture for each part to maximize part production due to increased vacuum efficiency. They utilize Baltic birch fixture boards and utilizes AllStar’s CR 25 25 In Board Gasket material. With a vacuum port through the fixture for each part, they have an air-tight seal as they produce.

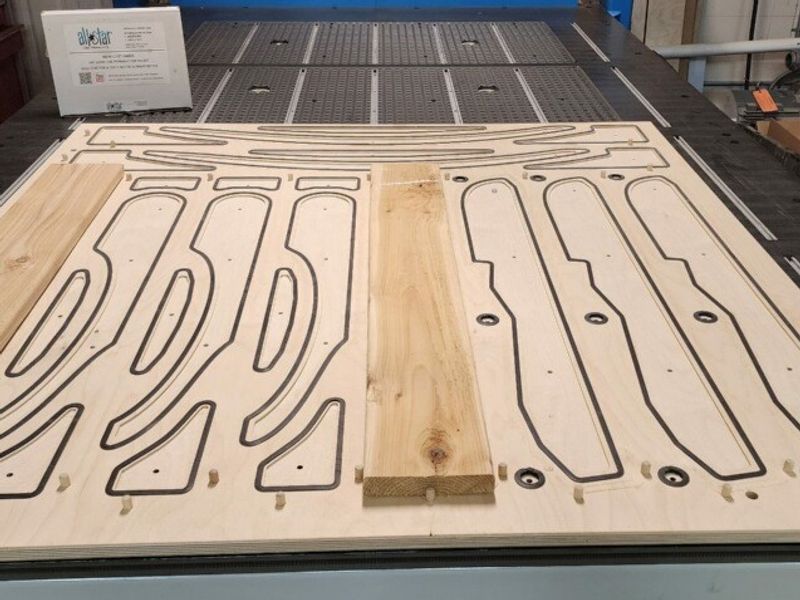

Antelope Run Woodshop (www.anteloperunwoodshop.com) makes Cedar and Redwood outdoor patio furniture in their Sierra Vista, AZ shop. They utilize their ShopSabre machine. They make their dedicated fixtures out of Baltic Birch and this photo shows AllStar’s CR 25 25In Board Gasket. This is a ¼” x ¼$ gasket with an adhesive on the bottom side. They do a great job of utilizing locating dowels in the fixture to ensure that parts line up in the

YouTube content creator WoodshopMike utilized All Star’s gasket in one of his videos making vacuum fixtures for making guitar parts on his ShopBot CNC Router (https://www.youtube.com/watch?v=1dUuGne0bS8). We worked through what his setup was, what he was looking to produce, and the type of vacuum system he had, and sent a variety of products for Mike to test with. We loved how he created a gasketed seal on the bottom of the fixture he built so that it can be set directly onto the spoilboard.

Ozark Mountain Furniture in Saligman, MO (https://ozarkmountainfurniture.com/) makes fine outdoor furniture. They do a great job creating dedicated fixtures utilizing CR 25 38 InBoard Gasket material on their fixtures. They do a great, unique design where they employ a melamine fixture board with Baltic birch “risers” sealed to the melamine, Everything is air-tight and the gasket ensures that the parts are clamped as solid as possible as the tooling cuts the parts. All done on his Laguna CNC table.

Scanline City in Indio, CA (www.skylinecity.com) uses a ShopBot CNC router to make retro gaming cases. Their team did a great job of creating a dedicated fixture using an HDPE fixture board, which will not leak vacuum or swell due to moisture. This is a repeat-use fixture board for a repeat part. The holes that are in the part have been gasketed for so as to not compromise the vacuum pocket area for the part.