Stories

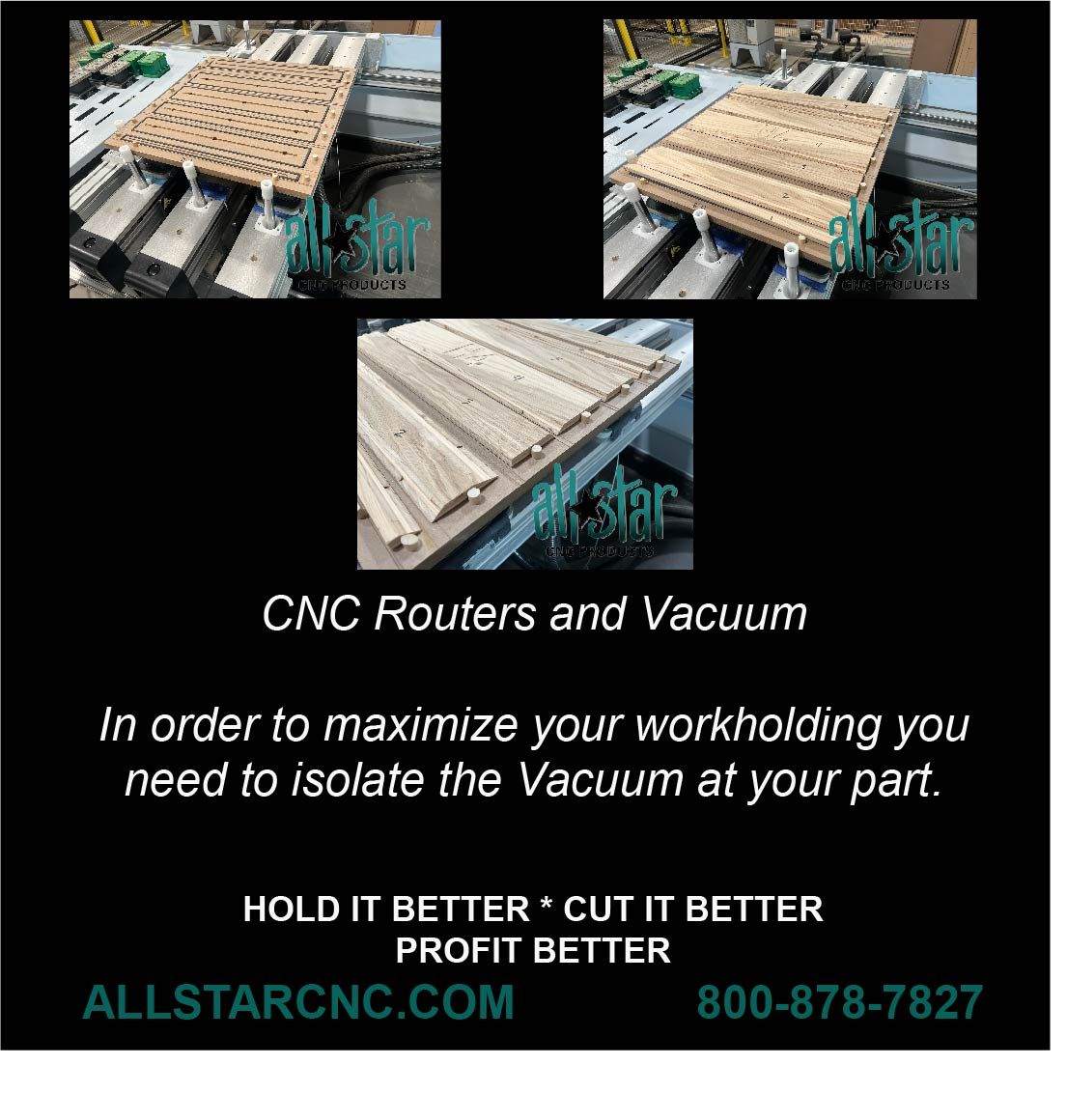

Pod and Rail CNC Router Dedicated Fixture

Every shop we deal with is unique. There are so many different variables that can change (type of router being used, type of material being cut, type of tooling being utilized, type of elevation being based, etc.) that no two shops are ever the same. But every customer that finds us is looking to address a difficulty that they all share: To improve the work-holding of the parts they are looking to vacuum down on their CNC router. We can help them do this is a variety of ways…

This particular customer last week called using multiple 5-axis pod-and-rail machines. Yet they called as they wanted to enjoy the benefits of a nesting table for a particular repeat job that they were looking to vacuum better. Needed the ability to route angled pieces out of a single sheet to later be miter-folded together. We talked them through the idea of making a dedicated fixture to fit over their pods. Used an in-board gasket to seal the vacuum chamber area under each part. Major improvement. Now that the proof of concept has worked, they will be making the same fixture out of a UHMW-type material to prevent leak through the current MDF set-up. Also mentioned to get their vacuum channels closer to the tool path as that is where the torque is occurring. Both of these improvements will result in improved vacuum performance on these particular parts.

The whole fixture set up will 100% percent result in more parts in less time, less waste and cleaner edge quality.

Hold It Better.

Cut It Better.

Profit Better.

If All Star CNC Products can help to improve the work-holding on someone’s CNC router, we will look forward to working with them. Our unique line of CNC Gasket products and concepts will have a specific solution for nearly every application that a customer will present to us. Parts don’t budge in air-tight systems. Gasket creates air-tight systems.